Copper Mould Tubes and Plates

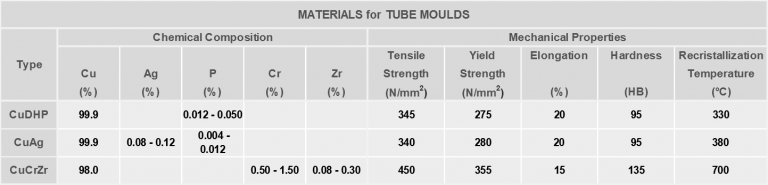

TUBE MOULDS

The most critical area in continuous casting is where the liquid steel turns into solid form. This is where the mould and related technologies come into existence to achieve successful and high-quality castings. ABAX with decades of experience in moulds and surrounding technologies, will direct you to the best solutions for success.

Productivity, operation and billet-quality are influenced to a large extend by the efficiency of the copper-moulds. High speeds of > 4 m/min require intensive and uniform heat-flux which can be achieved with innovative mould design.

Extra-long service-life is achieved with the special ABAX multilayer Ni-Co-Cr coating, which features high micro hardness and optimum binding strength with the copper base.

ABAX tubes are designed for maximum heat transfer rate from the meniscus down to the bottom of the tube. The taper-geometry depends on the steel-grades and casting conditions and is designed with the aim of minimizing the gap between the solidifying shell and the copper tube.

Extra-long service-life is achieved with the CerMold plating. This multilayer Ni-Co-Cr structure features high micro hardness and optimum binding strength with the copper base.

Advantages of ABAX Mould-Tubes:

- High casting speed

- Uniform shell growth

- No sticking

- Optimum billet quality

- Long service life

- Low cost

For high casting speeds ABAX has developed and designed the XXL copper tubes with extended length which are operating very successfully at a major steel-producer.

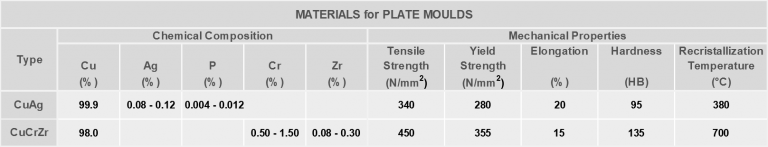

PLATE MOULDS

ABAX plates for bloom or slab-casters can be supplied with various types of surface-coatings:

High-speed billet casting 150 x 150 mm

- Maximum speed achieved above target with 4.375 m/min. Increase of 25% of design speed.

- Surface Quality good at all speeds with no internal or surface cracking detected. Zero rhomboid billets generated during trials.

- High Speed casting achieved with 40 degrees superheat with no detrimental effect on billet cross Section. No strand breakouts during trial.

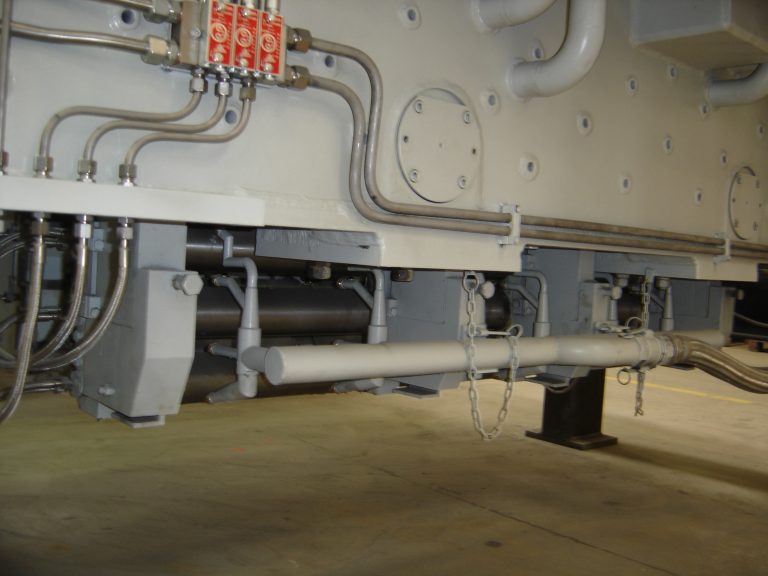

SLAB CASTERS

ABAX plates for slab-casters can be supplied with various types of surface-coatings: